Proper attic ventilation is crucial for maintaining a healthy and energy-efficient home. At Harvey Roofing & Construction, we see firsthand how roof ridge vent installations significantly improve air circulation, lowering attic temperature and eliminating moisture buildup in attics.

This comprehensive guide will walk you through the process of installing a roof ridge vent in the DFW area, from selecting the right layout to avoiding common pitfalls. Whether you’re a DIY enthusiast or considering professional installation, understanding the ins and outs of this important roofing component will help you make informed decisions for your home.

What Are Roof Ridge Vents?

Definition and Function

Roof ridge vents are essential components of an effective attic ventilation system. These long, narrow vents run along the primary peak of your roof and allow hot air and moisture to escape from your attic. The principle behind ridge vents is simple: hot air rises. As warm air accumulates in your attic, it naturally moves upward and exits through the ridge vent, creating a vacuum effect that draws cooler air from soffit vents at the eaves.

Benefits of Ridge Vents

Proper attic ventilation through ridge vents offers numerous advantages:

- Moisture Control: Ridge vents help prevent moisture buildup, which can lead to mold growth and wood rot. The National Roofing Contractors Association identifies moisture as the leading cause of premature roof failure.

- Extended Roof Life: By regulating attic temperature, ridge vents reduce thermal stress on roofing materials. This can extend your roof’s lifespan by up to 20% (according to studies by the Asphalt Roofing Manufacturers Association).

- Improved Energy Efficiency: A cooler attic in summer means less strain on your air conditioning system. Proper attic ventilation can reduce cooling costs by up to 10% in hot climates.

Selecting the Right Ridge Vent

When choosing a ridge vent, consider factors like your roof pitch, local climate, and aesthetic preferences. Not all homes are a candidate for roof ridge ventilation. The primary (highest point) ridge peak must have enough linear feet of ridge surface to allow for the adequate exhaust opening needed for your entire homes calculated exhaust air need. When utilizing a ridge vent it must be the only attic exhaust method and cannot be mixed with other exhaust ventilation types.

As we move forward to discuss the installation process, it’s important to note that while DIY installation is possible, professional installation (like that offered by Harvey Roofing & Construction) ensures optimal performance and longevity of your ridge vent system.

How to Install a Roof Ridge Vent

Gather the Right Tools and Materials

The installation of a roof ridge vent requires specific tools and materials. You’ll need a circular saw with a carbide-tipped blade, roofing nails, a hammer or nail gun, utility knife, chalk line, the ridge vent fixtures, and ridge cap shingles. Don’t forget personal protective equipment such as safety glasses, work gloves, and non-slip shoes.

Proper ventilation is best achieved by having both ridge ventilation (high) for exhaust and eave edge (low) for intake of cooler air. A balanced ventilation system is imperative for proper air movement in the attic.

Prepare the Roof and Ensure Safety

Safety should be your top priority. Use a sturdy ladder that extends at least 3 feet above the roof edge and placed at a 75 degree angle (1 foot away from wall for every 4 feet of wall height). If your roof pitch exceeds 6/12 or is more than one story high, consider using a safety harness.

Remove the cap shingles along the ridge. Use your utility knife to cut through any sealant holding them in place. Take care not to damage the underlying shingles.

Cut the Roof Deck

This step requires precision. Use your chalk line to mark cutting lines on both sides of the ridge, leaving an approximate 1-inch open gap on each side of the peak.

Use your circular saw to carefully cut along these lines. Set the blade depth to cut through the sheathing but not the rafters beneath. Remove any debris from the cut area.

Install the Ridge Vent

Now it’s time to install the actual ridge vent fixtures. Start at one end of the ridge and work your way to the other. Most ridge vents come in 4-foot sections that you can easily cut to fit your roof’s length.

Nail the vent securely every 12 inches on both sides. Make sure the vent sits flat against the roof surface. Any gaps could allow water infiltration.

Secure Shingles Over the Vent

The final step involves covering the vent with cap shingles. Nail them securely with adequate length ring shank nails (commonly provided with the ridge cap fixture), but be careful not to over drive nails.

While this guide provides a general overview, ridge vent installation is a complex task. Professional installation ensures that every step is executed with precision, guaranteeing optimal performance and longevity of your roofing system. In the next section, we’ll discuss common mistakes to avoid during the installation process, helping you achieve the best results for your roof ventilation system.

Avoiding Common Ridge Vent Installation Pitfalls

Incorrect Sizing and Placement

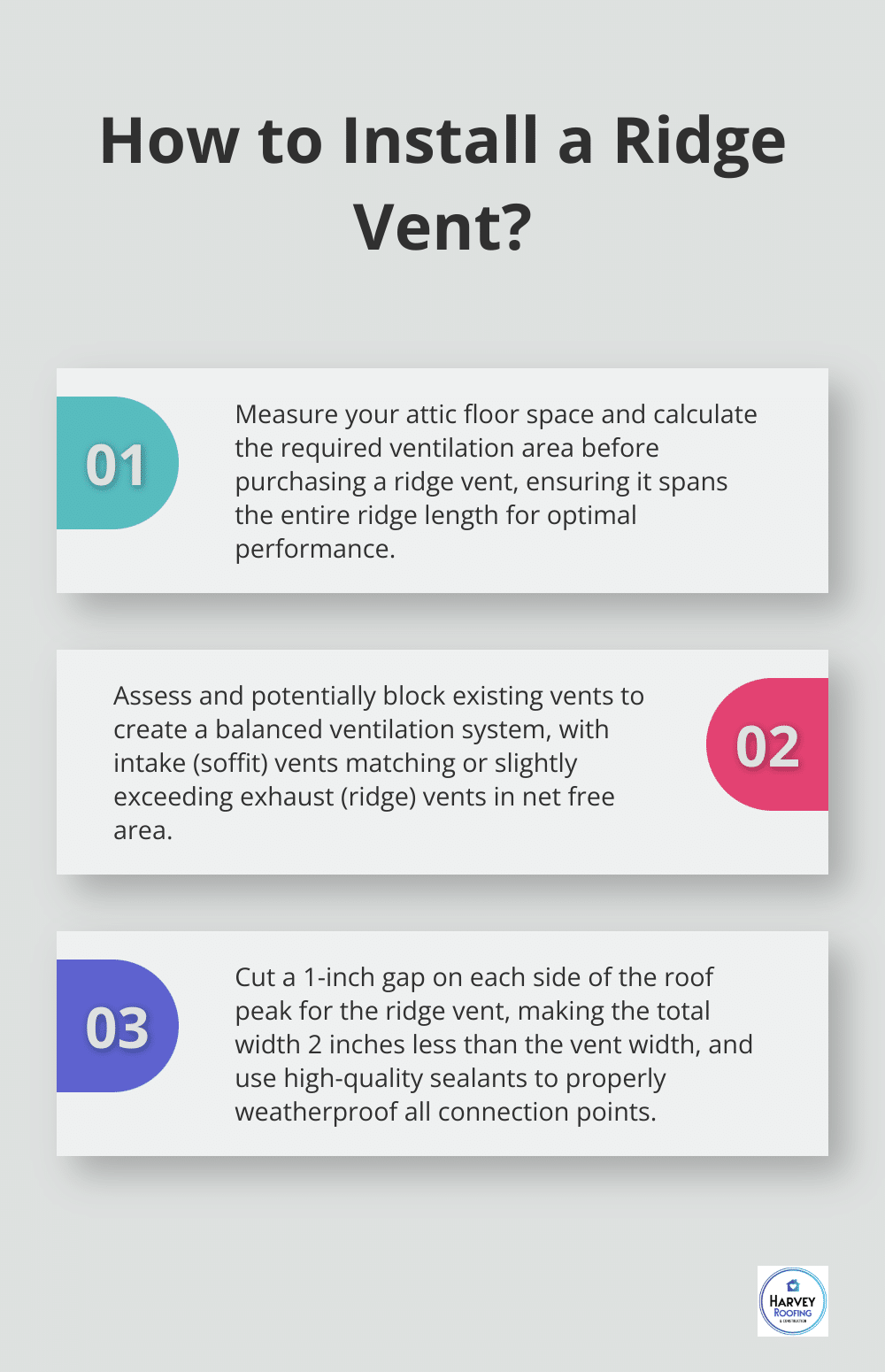

The size and placement of ridge vents play a critical role in their effectiveness. To ensure proper ventilation for your home, it’s important to calculate the correct amount of attic ventilation needed. This calculation takes into account factors such as attic floor space, local climate, and building codes.

Undersized vents lead to poor ventilation, while oversized ones can cause excessive airflow (potentially allowing water infiltration during severe weather). The vent should span the entire primary ridge length for optimal performance. Gaps or shortened installations create dead spots where hot air and moisture accumulate.

To reiterate, not all homes are a candidate for roof ridge ventilation. The primary (highest point) ridge peak must have enough linear feet of ridge surface to allow for the adequate exhaust opening needed for your homes calculated exhaust air need. When utilizing a ridge vent it must be the only attic exhaust method and cannot be mixed with other exhaust ventilation types.

Neglecting Existing Ventilation Systems

Many installers overlook the existing ventilation when adding ridge vents. This oversight can create an imbalance in airflow, reducing the overall effectiveness of attic ventilation.

A thorough assessment of the current setup (including any existing exhaust, soffit and gable vents) is essential before installation. Some existing vents may need to be blocked or removed to ensure proper air circulation with the new ridge vent.

The Building Science Corporation advocates for a balanced system where intake (soffit) vents match or slightly exceed exhaust (ridge) vents in net free area. This balance promotes steady airflow from the bottom to the top of the attic space.

Inadequate Weatherproofing

Poor sealing often leads to leaks, which can cause significant damage to the roof structure and attic over time. The International Association of Certified Home Inspectors lists roof leaks (often due to improper installation or sealing of components like ridge vents) as one of the top ten problems found during home inspections.

High-quality sealants and strict adherence to manufacturer instructions are essential for proper weatherproofing. Special attention should be paid to areas where the vent sections connect.

Overlooking Local Building Codes

Building codes vary by location and failure to comply can result in required repairs, or even complete reinstallation. Some areas have specific requirements for ridge vent installation, including minimum ventilation ratios, approved materials, and installation methods.

Before starting any ridge vent installation, check local building codes and obtain necessary permits. This step ensures the project meets all legal requirements and safety standards.

Improper Cutting of the Roof Deck

The precision of the roof deck cut affects the ridge vent’s performance and the roof’s structural integrity. Common mistakes include cutting too wide (causing leak risks) or too narrow (which restricts airflow).

Most ridge vents require a 1-inch gap on each side of the roof peak. Use a chalk line to mark precise cutting lines and set the circular saw blade depth to cut through the sheathing but not the rafters beneath.

Final Thoughts

Roof ridge vent installation plays a vital role in maintaining a healthy and energy-efficient home. This complex task requires precision, knowledge, and experience to ensure optimal performance. Professional services offer homeowners the expertise needed to navigate local building codes, perform accurate installations, and integrate new vents with existing systems.

Harvey Roofing & Construction specializes in professional roof ridge vent installation, using high-quality materials for optimal results. Our team’s expertise helps extend the life of your roof and improve your home’s energy efficiency.

Professional installation of ridge vent exhaust ventilation enhances energy efficiency and contributes to a healthier home. Investing in proper roof ridge vent installation is an investment in your home’s longevity and comfort.

Harvey Roofing & Construction

817-422-4847

www.HarveyRoofingTX.com

5712 Regalview Dr

Joshua, TX 76058