Standing seam metal roof installation is a game-changer in modern roofing. At Harvey Roofing & Construction, we’ve seen firsthand how this durable and stylish option has transformed homes and businesses.

Our comprehensive guide will walk you through the entire process, from preparation to the final touches. Whether you’re a curious homeowner or a roofing professional looking to expand your skills, this post has something for everyone.

What Are Standing Seam Metal Roofs?

Standing seam metal roofs represent a premium roofing solution that has gained popularity in both residential and commercial buildings. These roofs consist of vertical metal panels that extend from the ridge of the roof to the eaves. The panels join together with raised seams that interlock, creating a distinctive linear look and a watertight seal.

Components of Standing Seam Metal Roofs

The main components of a standing seam metal roof include:

- Metal panels (typically steel, aluminum, or copper)

- Clips

- Fasteners

Steel stands out as the most common choice due to its durability and cost-effectiveness. Clips and fasteners secure the panels to the roof deck while allowing for thermal expansion and contraction.

Types of Standing Seam Metal Roofs

Several types of standing seam metal roofs exist, each suited for different applications:

- Snap-lock panels: Popular for residential use, these require a minimum roof pitch of 3/12. They offer easier installation but may not provide as much weather protection as other options.

- Mechanical lock panels: These come in single or double-locked varieties. They offer superior weather resistance and work well for low-slope roofs or areas with harsh weather conditions.

Benefits of Standing Seam Metal Roofs

Standing seam metal roofs offer numerous advantages over traditional roofing materials:

- Durability: With proper installation and maintenance, these roofs can last 50 years or more.

- Cost-effectiveness: Despite higher initial costs, their longevity translates to significant long-term savings.

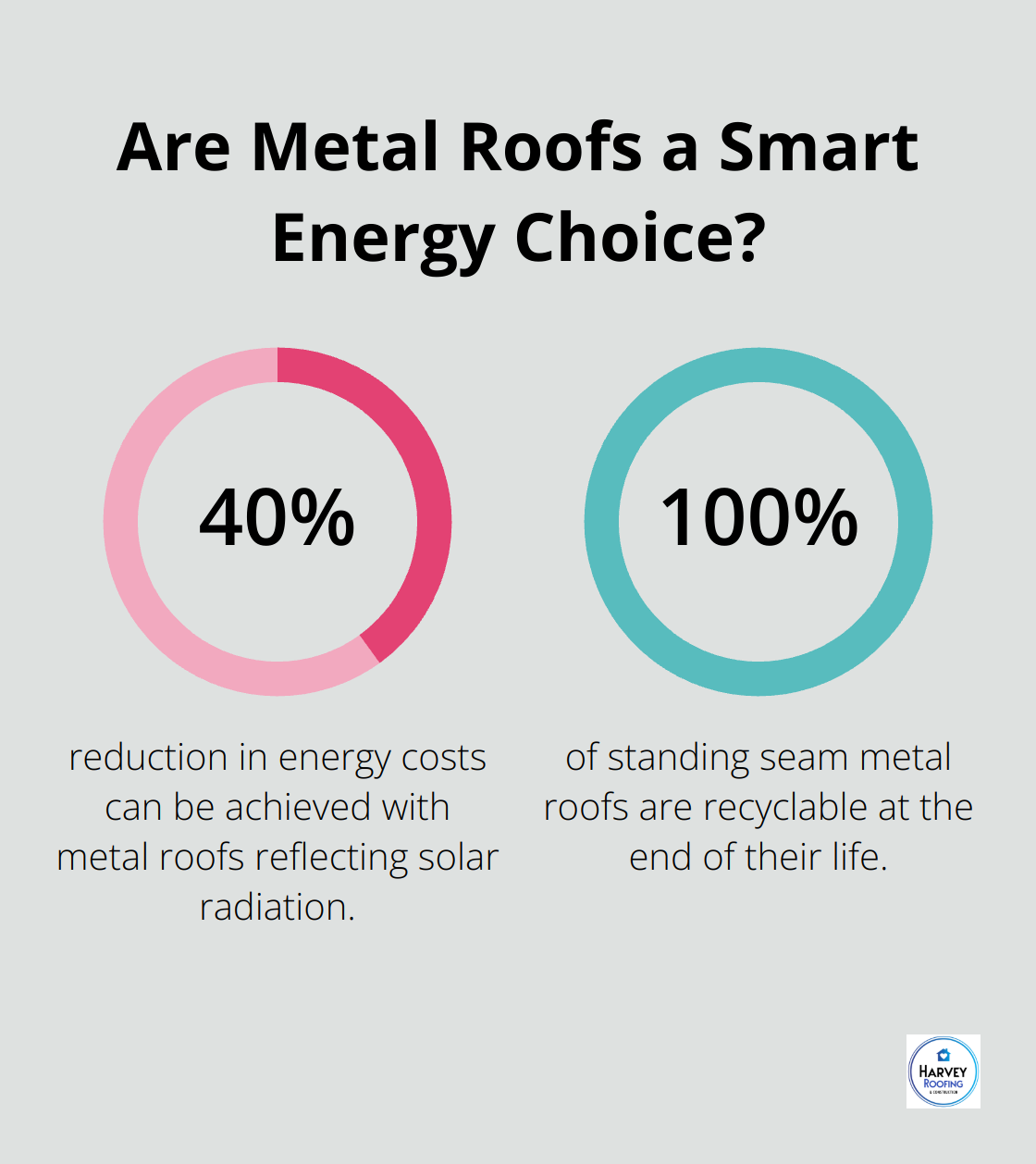

- Energy efficiency: Metal roofs reflect solar radiation, which can reduce energy costs by up to 40%.

- Environmental friendliness: Often made from recycled materials, these roofs are 100% recyclable at the end of their life.

- Weather resistance: The interlocking design makes them highly resistant to wind uplift (some systems rated for winds up to 180 mph).

Installation Considerations

The installation of standing seam metal roofs requires specialized skills and tools. Professional installers must account for factors such as:

- Proper panel alignment

- Correct fastener placement

- Allowance for thermal movement

- Weathertight sealing at all joints and penetrations

As we move into the next section, we’ll explore the critical steps involved in preparing for a standing seam metal roof installation. This preparation phase sets the foundation for a successful and long-lasting roofing system.

How to Prepare for Standing Seam Metal Roof Installation

Comprehensive Roof Inspection

A thorough roof inspection marks the first step in preparing for a standing seam metal roof installation. Professional roofers assess the existing roof structure, looking for signs of damage or weakness. They check for issues like rotted decking, sagging areas, or structural problems that could compromise the new roof’s integrity.

During this inspection, roofers take precise measurements. Accurate measurements are vital for ordering the correct amount of materials and ensuring a perfect fit for the new standing seam metal roof. This step helps minimize waste and keeps project costs in check.

Removing Existing Roofing Materials

After the inspection, the next step involves removing the old roofing materials. This process requires care and precision to avoid damaging the underlying structure. Specialized tools strip away old shingles, underlayment, and flashing.

In some cases, it’s possible to install a standing seam metal roof over existing shingles. However, this approach is not always recommended as it can hide underlying issues and potentially void warranties. The National Roofing Contractors Association advises complete removal of old roofing materials for best results.

Installing Underlayment and Flashing

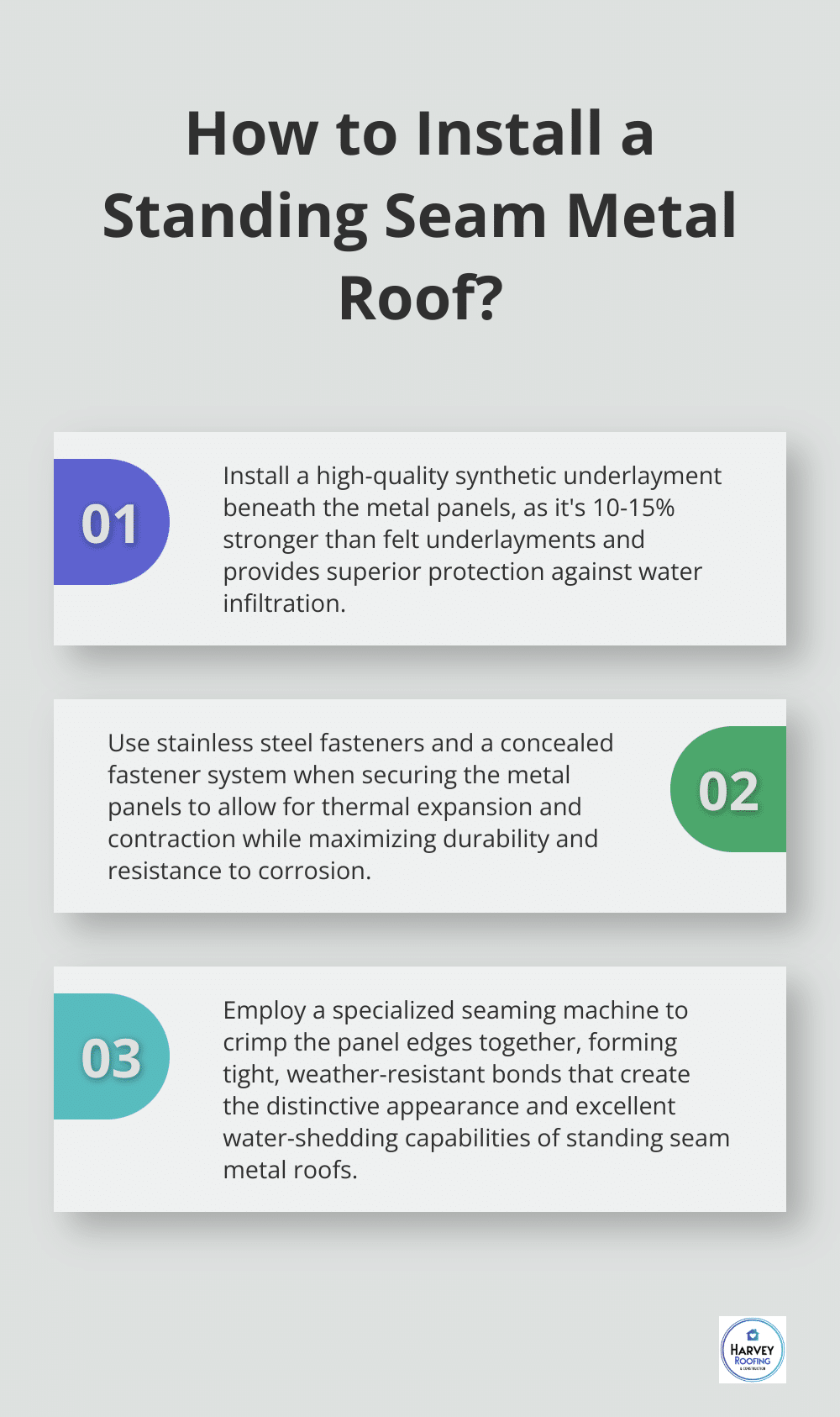

With the old roofing materials removed, it’s time to lay the foundation for the new standing seam metal roof. This starts with installing a high-quality underlayment. Synthetic underlayments are often preferred due to their superior strength, being 10-15% stronger than felt underlayments.

Proper flashing installation prevents water infiltration. Roofers apply flashing around all roof penetrations, including chimneys, vents, and skylights. They pay special attention to valleys and eaves (areas particularly vulnerable to water damage).

For standing seam metal roofs, a high-temperature ice and water shield in these critical areas provides an extra layer of protection. This additional safeguard is especially important in regions prone to ice dams or heavy rainfall.

Preparing the Roof Deck

The roof deck must be in excellent condition to support the new standing seam metal roof. Roofers inspect the decking for any signs of rot, warping, or damage. They replace any compromised sections to ensure a solid foundation for the new roof.

Proper ventilation is also addressed during this stage. Adequate airflow in the attic space prevents moisture buildup and extends the life of the roofing system. Roofers may install additional vents or improve existing ventilation systems as needed.

The preparation phase sets the stage for a successful standing seam metal roof installation. With a solid foundation in place, the next step involves the actual installation process, where the metal panels transform the roof into a durable and aesthetically pleasing protective barrier.

How Professionals Install Standing Seam Metal Roofs

Laying the Foundation

The installation process starts with the placement of starter strips and eave flashing. These components create a secure base for the metal panels and ensure proper water drainage. Professional roofers use high-quality, corrosion-resistant materials for these elements to maximize the roof’s longevity.

Roofers then carefully lay out the first metal panel. Proper alignment at this stage sets the pattern for the entire roof. They use laser levels and specialized measuring tools to ensure perfect placement. Each subsequent panel is positioned with meticulous care, maintaining consistent spacing and alignment.

Securing the Panels

Once positioned, roofers secure the panels using a system of clips and fasteners. These components allow the metal to expand and contract with temperature changes without compromising the roof’s integrity. The National Roofing Contractors Association recommends concealed fastener systems for standing seam roofs, as they reduce wear and tear, while the durable metal panels resist damage from pests, UV rays, and rot.

Most professionals use stainless steel fasteners due to their exceptional durability and resistance to corrosion. The number and placement of fasteners depend on factors like wind load requirements and panel width. In high-wind areas, additional fasteners may be necessary to ensure the roof meets local building codes.

Creating Watertight Seams

After securing the panels, roofers focus on creating watertight seams. This process, known as seaming, gives standing seam metal roofs their distinctive appearance and excellent water-shedding capabilities. Specialized seaming machines crimp the panel edges together, forming a tight, weather-resistant bond.

The seaming process requires skill and experience. Improper seaming can lead to leaks and reduce the roof’s overall performance. Professional roofers undergo extensive training in this critical step, ensuring each seam is perfectly formed.

Finishing Touches

The final stage of installation involves adding ridge caps and trim. These components not only enhance the roof’s appearance but also provide additional protection against water infiltration at vulnerable points. Roofers often custom-fabricate these elements on-site to ensure a perfect fit for each unique roof.

Throughout the installation process, professional roofers maintain strict quality control measures. They inspect each step before moving on to the next and perform a comprehensive final inspection upon completion. This attention to detail is why professionally installed standing seam metal roofs consistently outperform and outlast other roofing options.

Installing a standing seam metal roof is a complex process that demands skill, precision, and the right tools. While DIY enthusiasts might be tempted to tackle this project, professional installation is important for ensuring the roof’s performance and longevity. With proper installation, a standing seam metal roof can protect a home or business for decades (making it a wise investment in a property’s future).

Final Thoughts

Standing seam metal roof installation requires precision, expertise, and specialized tools. Professional roofers bring essential skills to handle the complexities of the process, ensuring proper alignment, secure fastening, and weathertight sealing. These roofs offer exceptional durability, often lasting 50 years or more with proper maintenance, while providing superior protection against harsh weather conditions.

Harvey Roofing & Construction understands the importance of quality workmanship in standing seam metal roof installations. Our team of skilled professionals executes every step with precision and care, using high-quality materials and following industry best practices. We strive to deliver roofing solutions that stand the test of time, enhancing both the aesthetic appeal and protection of your property.

A professionally installed standing seam metal roof represents a wise long-term investment for your property. It combines durability, energy efficiency, and low maintenance requirements (qualities that homeowners and businesses value highly). With its unparalleled protection and aesthetic appeal, a standing seam metal roof provides peace of mind for decades to come.

Harvey Roofing & Construction

817-422-4847

www.HarveyRoofingTX.com

5712 Regalview Dr

Joshua, TX 76058